Quality management software (QMS) for manufacturing is a specialized tool designed to enhance the quality control and assurance processes within manufacturing organizations. These software solutions are essential in managing, monitoring, and improving product quality throughout the production lifecycle. They integrate various functions such as quality planning, quality control, quality assurance, and continuous improvement, providing a comprehensive approach to maintaining high standards in manufacturing operations.

Core Functions of Quality Management Software

a. Document Control: Quality management software often includes document control features that allow manufacturers to manage quality documentation such as standard operating procedures (SOPs), work instructions, and quality manuals. This functionality ensures that documents are up-to-date, easily accessible, and properly distributed across the organization.

b. Quality Control and Assurance: The software facilitates the implementation of quality control measures such as inspection plans, test procedures, and data collection. It helps in tracking defects, managing non-conformances, and ensuring that corrective and preventive actions (CAPA) are taken promptly. It also supports quality assurance activities, ensuring compliance with industry standards and regulations.

c. Audits and Compliance: QMS solutions assist in planning, executing, and managing internal and external audits. They help ensure that the manufacturing processes comply with various standards like ISO 9001, IATF 16949, and FDA regulations. The software helps in managing audit trails, documenting findings, and tracking the resolution of non-conformities.

d. Risk Management: Risk management is another crucial aspect where QMS software plays a role. It helps identify potential risks in manufacturing processes, assess their impact, and implement risk mitigation strategies. This proactive approach helps in minimizing defects, reducing waste, and improving overall product quality.

e. Continuous Improvement: Quality management software supports continuous improvement initiatives by providing tools for analyzing quality data, identifying trends, and implementing improvement actions. It often includes features for managing lean manufacturing practices, Six Sigma projects, and other quality improvement methodologies.

Benefits of Quality Management Software

a. Improved Efficiency: By automating and streamlining quality management processes, the software reduces manual tasks and administrative overhead. This efficiency enables manufacturers to focus more on core production activities and less on paperwork.

b. Enhanced Data Accuracy and Visibility: QMS software centralizes quality data, making it more accurate and accessible. This centralized data repository enables better visibility into quality metrics and performance, facilitating informed decision-making and timely interventions.

c. Compliance and Risk Mitigation: Ensuring compliance with industry standards and regulations is crucial for manufacturers. QMS software helps in maintaining compliance by managing documentation, tracking compliance activities, and providing audit trails. It also aids in risk identification and mitigation, reducing the likelihood of quality-related issues.

d. Customer Satisfaction: Improved quality control and assurance lead to higher product quality, which directly impacts customer satisfaction. By reducing defects and improving product reliability, manufacturers can enhance their reputation and strengthen customer relationships.

e. Cost Savings: Effective quality management can lead to significant cost savings by reducing rework, scrap, and warranty claims. By addressing quality issues proactively and preventing defects, manufacturers can avoid the costs associated with poor quality.

Key Features to Look for in Quality Management Software

a. Integration Capabilities: The software should integrate seamlessly with other enterprise systems such as Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), and Laboratory Information Management Systems (LIMS) to ensure a cohesive flow of information.

b. User-Friendly Interface: An intuitive and user-friendly interface is essential for ensuring that the software is easily adopted by employees across the organization. The software should be easy to navigate and require minimal training.

c. Customization and Scalability: Manufacturers should look for QMS software that can be customized to fit their specific processes and scaled to accommodate growth. Customizable features allow organizations to tailor the software to their unique quality management needs.

d. Real-Time Analytics and Reporting: Real-time analytics and reporting capabilities are crucial for monitoring quality performance and making data-driven decisions. The software should provide customizable dashboards, reports, and alerts to keep stakeholders informed.

e. Support and Training: Effective support and training are vital for successful implementation and ongoing use of the software. Manufacturers should choose a provider that offers comprehensive support and training resources to ensure a smooth transition and effective utilization of the software.

Compliancequest

ComplianceQuest’s Manufacturing Quality Management System (QMS) software automates the entire process of quality issues from problem identification through assessment, disposition, corrective measures, to change control in a centralized system.

- Satisfying Customer Expectations

- Establish Your Brand Recognition

- Better recommendations

- Minimized Customer Complaints and Returns

- Managing Complaints

- Improved Cost Management

Solidworks

Solidworks – delmiaworks (formerly IQMS) Quality Management Software offers tools for QMS control, elevating operations and resolving quality issues effectively.

- Advanced Product Quality Planning – APQP/PQ

- Corrective Action Request – CAR/CAPA

- Cost of Quality

- Device History Record and PLM

- Document Control

- Engineering Change Order System – ECO

- Material Review Board – MRB

- Production Part Approval Process / Product PQ – PPAP/PQ

- Quality Audit

- Statistical Process Control – SPC

Syspro

SYSPRO’s Quality Management module is a vital tool for manufacturers seeking to enhance their quality control with automated software.

- Set up quality tests

- Test design and configuration

- Set tolerance values

- Configure acceptance quality limits

- Link tests to stock codes and suppliers

- Review test statuses

Assurx

AssurX manufacturing quality management system automates quality processes within a centralized platform between and quality improvement.

- No-code configurability

- Collaboration Through Process Automation

- Centralized Documentation

- High Visibility

- Robust analytics

- Greater Accountability

- A Centralized Quality Management Software Platform

Qualityze

Qualityze – quality Management Software for Manufacturing Industry tailored to comply with industry standard ISO 9001 for continuous improvement and compliance.

- User-Friendly Interface

- Seamless Integration

- Cloud-Based Platform

- Automated Upgrades

- Configurable workflows and Fields

- Low-Cost Implementation

- Low Maintenance Cost

- Flexible and Secure

Aiscorp

Aegis Software enables industrial manufacturing excellence by improving control and visibility with an adaptable MES system built on an IIoT backbone.

- Quality Products Must Begin with Quality Materials

- Identify, Diagnose & Resolve Defects In-Process

- The Right Information, at the Right Location, and Right Time

- Automate a Proactive Approach to Quality

- Achieve Instant Visibility

- Drive Organizational Alignment by Eliminating Data Silos

- Predictive Quality & Trends

Mastercontrol

MasterControl quality management system for manufacturing enable regulated enterprises get their products to market faster and maintain compliance.

- A single platform that securely stores all product information

- Thoroughly connected quality processes

- A central repository for all manufacturing procedures, bills of materials and other essential documentation

- An interface that makes all supplier-related data easily accessible, which simplifies assessments and monitoring

- Seamless integration with common tools like Word, Outlook, CAD, etc.

- A connected product life cycle that makes it easier to infuse quality feedback into future product designs

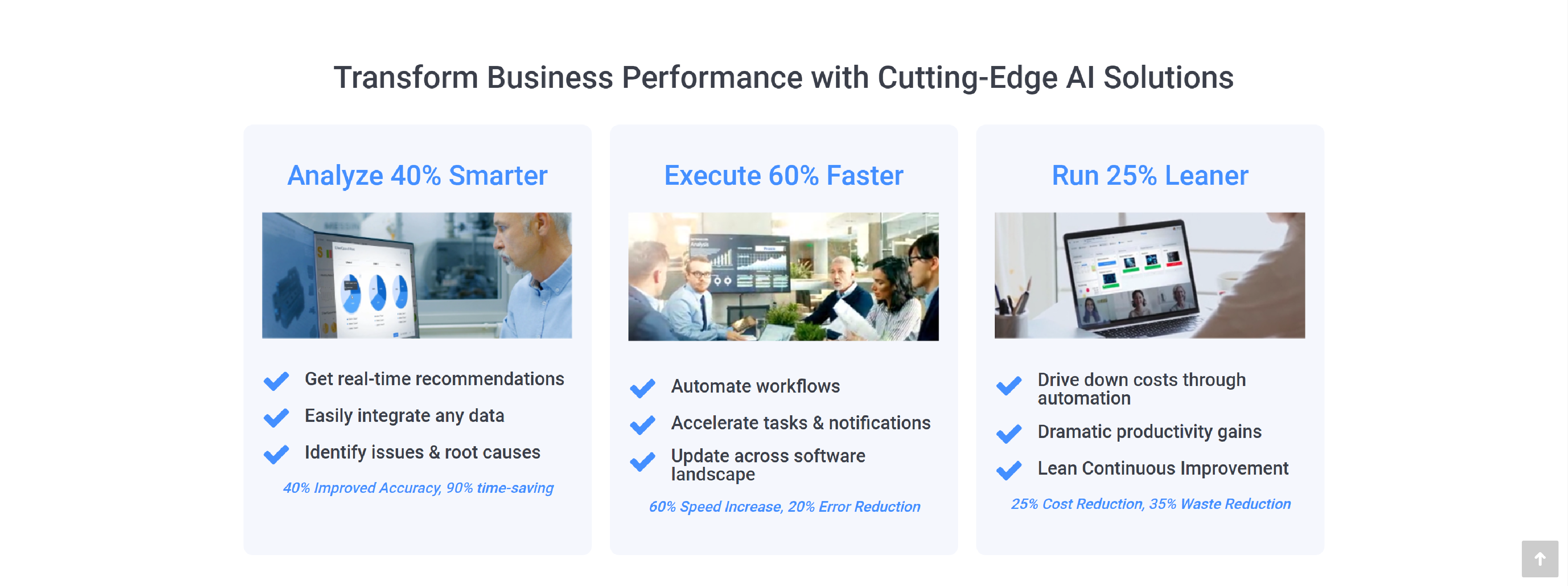

Praxie

Praxie Quality Management System Software App for Manufacturing boosts effiiency, streamlines processes, and enhances digital manufacturing.

- AI-Powered Enhanced Visibility and Waste Reduction

- Improved Efficiency, Productivity and Decision Making

- Customer Focus, Cost Reduction and Process Improvement

Advantive

Advantive QMS solution provides a formalized platform that accurately tracks product specifications, documents processes, manages industry regulations, and helps you consistently meet quality standards.

- Consistently meet quality standards with a documented quality management system

- Eliminate the uncertainties and risk of product traceability

- Easily adjust to changes in production processes or product specifications based on real-time data and testing

Wm-synergy

WM Synergy brings together a collaborative team of experts, best-in-class ERP business solutions, and proven best practices to create tailored solutions for manufacturing, distribution, and e-commerce companies.

- A Competitive Advantage

- Key Performance Indicators

- Unify Departments & Data

- Automate Approvals

- Industry Standard Compliance

- Increase Reaction Speed

Quality Management Software (QMS) For Manufacturing: Frequently Asked Questions

What is Quality Management Software (QMS) for Manufacturing?

Answer: Quality Management Software (QMS) for manufacturing is a digital solution designed to manage and improve the quality of products and processes in manufacturing environments. It helps manufacturers ensure that their products meet required quality standards and regulatory compliance by providing tools for document control, quality control, quality assurance, risk management, and continuous improvement.

Why is QMS important for manufacturing companies?

Answer: QMS is crucial for manufacturing companies because it helps maintain high-quality standards, comply with industry regulations, and improve operational efficiency. By systematically managing quality processes, manufacturers can reduce defects, enhance customer satisfaction, minimize waste, and avoid costly recalls or rework. It also supports continuous improvement initiatives and helps in managing risks and compliance effectively.

How does QMS software improve manufacturing efficiency?

Answer: QMS software improves manufacturing efficiency by automating and streamlining quality management processes, reducing manual paperwork, and minimizing errors. It centralizes quality data, making it easily accessible for analysis and decision-making. Automation of tasks such as document control, inspection planning, and non-conformance tracking speeds up processes and allows manufacturers to focus on core production activities.

How does QMS software assist with compliance and risk management?

Answer: QMS software assists with compliance by managing documentation, tracking compliance activities, and providing audit trails to ensure adherence to industry standards and regulations. For risk management, the software helps identify potential risks, assess their impact, and implement mitigation strategies. It tracks risk management activities and ensures that corrective actions are effectively executed.

Can QMS software be customized for different manufacturing processes?

Answer: Yes, many QMS software solutions offer customization options to fit various manufacturing processes. This includes tailoring workflows, document templates, inspection criteria, and reporting formats to align with specific operational requirements. Customization ensures that the software addresses the unique needs of different manufacturing environments.

How does QMS software support continuous improvement?

Answer: QMS software supports continuous improvement by providing tools for data analysis, trend identification, and performance monitoring. It facilitates the implementation of quality improvement methodologies such as Six Sigma and lean manufacturing. The software helps track the effectiveness of improvement initiatives, manage change requests, and document lessons learned, fostering a culture of ongoing enhancement.

QMS software is an essential tool for manufacturing organizations aiming to maintain high-quality standards, ensure regulatory compliance, and continuously improve their operations. By addressing core functions such as document control, quality assurance, and risk management, QMS software provides significant benefits in terms of efficiency, data accuracy, and overall product quality.